Introduction

Backed by a buoyant demand from the construction industry, the market for steel long products such as rebars, I-Beams, Angles etc. is expected to grow at a healthy rate over the next five years. The year 2018-19 has particularly seen the revival of steel production in several global markets, both developed and developing ones. But one key trend that sets this revival apart is the increased interest in automation of steel production in the workshop and finished goods line.

Source: 2019 Report by Worldsteel Association (https://www.worldsteel.org/media-centre/press-releases/2019/world-steel-in-figures-2019.html)

There are two primary forces behind technology upgrade and greater use of automation in Steel Roll shops. These include plant performance efficiency, and reduced running costs. Also, aiding are the relatively lower costs of advanced electronics and control systems along with increased penetration of robotics.

Sparkonix has been serving the Roll Shops in over 45 countries for over two decades now. We observe three key forces behind the greater interest in automation by Steel Roll Shops, large and small, in every market we serve.

The shift to automation of Roll Shops is evident in many ways. Typically the trajectory is as below:

The flattening of prices requires better control over unit costs

With super efficient global supply chains, the cost of moving heavy materials, whether its the minerals, scraps or finished goods has been reducing over the years. This in turn has led to flattening of prices in key markets. In our experience of over two decades of serving the steel industry, the desire to achieve accurate control over the cost of production is at the peak, today.

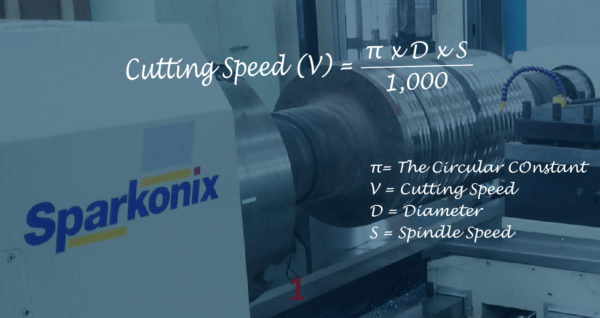

Automation of Roll Shops by adopting the CNC Turning Lathe, and use of CNC Notching + Branding Machines has enabled manufacturers of Steel products to accurately control the costs. With manual Lathes, the difference in throughput and quality of output varied significantly and was generally difficult to control. Upgrade of Roll shops to CNC Machining, with its greater repeatability and consistency, helps to overcome both these challenges and thereby reduce the overall unit costs.

Quality is the key to success, no matter the size of the company

Traditionally, the Steel Business has been about scale. It’s the larger players setting the standards for the quality and usually the relatively smaller players doing the catching-up. But the trend is changing across the markets. Over the last few years, with access to advanced technology and greater affordability, even the small to mid-sized players are staying ahead in the ‘quality’ game.

In addition to the largest Steel makers, many of Sparkonix’s machines are used by mid-sized plants. Given the optimised price and superior performance of Sparkonix’s CNC Roll Turning Lathe, it has been a preferred choice of Roll Shops in growing mills in developing markets. Increasingly, we have observed that even the small and mid-sized manufacturers are setting a goal to follow the global ‘quality’ benchmarks.

Branding to guard premium pricing and improve profitability

Branding of steel rebars and other products with names of the company and unique notch patterns has been a trend, especially in the developing markets. While the trend itself was started back in early 2000’s by the large manufacturers such as Tata Steel and Jindal Steel, over the years the relatively small and mid-sized manufacturers also found a lot of value in the technology.

The branding and unique notch patterns helps the small and medium manufacturer to differentiate their products and charge a premium in a intensely competitive market where margins are often 5% or less. Several customers have leveraged Sparkonix’s Notching and Name marking machine to craft their brands and improve profitability. Over the last 2 decades, Sparkonix has advised over 1000 Roll Shops to develop their desired unique brands and notch patterns for the products.

Conclusion

The trend of automation of Roll Shops is only going to grow. With a range of options, proven technology and trust from over 1250 Rolling Mills Sparkonix is a highly capable solution provider for the Roll Shops.

Further scope of automation in other time consuming tasks such as handling of rolls is already gaining popularity. This includes transfer, loading and unloading of Steel or Carbide rolls on the Roll Shop machining equipment.