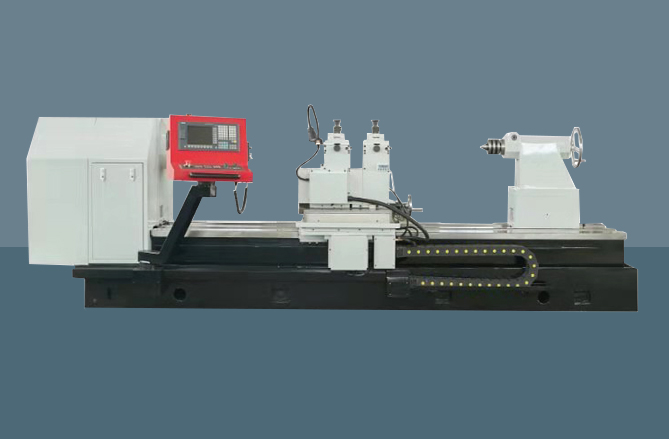

CNC Twin Head Notching Machine

CNC Twin Head Notching Machine – 5500

Improve productivity with two cutting heads

In continuation of our long term endevour to offer the Best solution to our customer Sparkonix has launched the TWIN HEAD NOTCHING MACHINE. This machine is capable of machining 2 pass forms simultaneously and increase productivity. The machine is designed to adapt Heavy Rolls and has now a modified Arbour design to ensure increased stability and increase Tool cutter life.

Machine Tools Features

- Twin cutting heads

- 4 axes CNC machine

- 3 Axis simultaneous movement of CNC control system

- Vertical type Fly Cutter spindle is used to cut notches

Advantages

- Near to double productivity with single operator

- Machine any angle of the rib with input of the angle needed to be cut

- Even shape of Ribs throughout the pass

- All Ribs having same depth with automation means less dependency on operator skill

- Skipping, Omitting, Enlarging of ribs is possible

Automatic Centre Referencing Probe

- Significant eduction in manual effort and skill

- Accurate pass/groove centering

- Easy, fast and accurate centering of notches

- Possible to re-notch on existing notches

- Easy center finding for marking

- Safety interlock protection to avoid probe damage during notch cutting operation

Technical Specification

| Parameters | Specification |

| Max Roll Dia | 550 mm |

| Min Roll Dia | 100 mm |

| Max Roll Length | 2500 mm |

| Suitable Rebar Spec | 5-50 mm |

| Cutting Type | Double Fly Cutter |

| Main Motor Y Axis | 21.5 nm(4.5 kw) |

| Max Cutting Speed | 650 rpm |

| Workpiece Material | Cast Iron Roll, Hss Roll, Carbide Composite Roll/Ring |

| A Axis (Double Flyer) Motor Power | 21.5 nm(4.5kw) |

| X Axis (Cross Feed) | 15 nm (2.36kw) |

| B Axis (Longitudinal) | 15 nm (2.36kw) |

| Accuracy | 0.00 1mm |

| Headstock Spindle Taper | MS#5 |

| Tailstock Spindle Taper | MS#6 |

| Coolant Pump | 90 W |

| Max Load | 3000 Kgs/ 3 Ton |

| Machine Weight | 6.5 t |

| Overall Dia | 4500 x 1800 x 1900 mm |